Most people who sew are aware of the need to adjust the tension on their sewing machines. Adjusting the tension is a matter of give and take. What many people don’t realize is there is more to the tension issue than just twisting the knob on the arm of the machine. Understanding how sewing machine tension works is vital to making the correct adjustments to your machine.

The Tug of War – Tension Adjustments

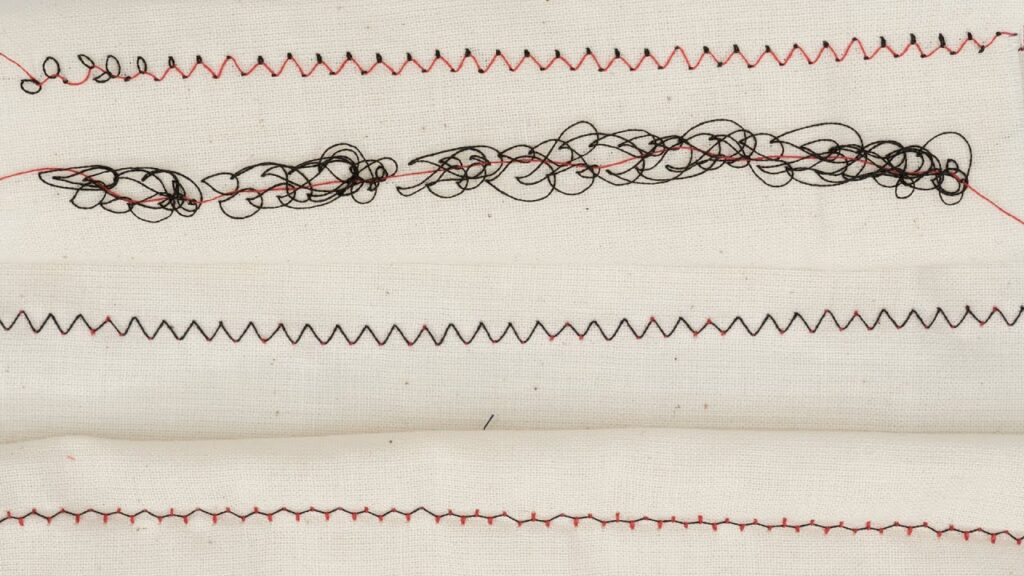

The easiest way I have found to describe how tension on a sewing machine works is to think about a game of tug of war. Imagine two teams of players on either end of rope pulling in opposite directions. Your sewing machine does almost exactly the same thing as it forms a stitch. To for that perfect stitch, the pull between the top thread and the bottom thread has to be almost equal. If one or the other is out of balance problems occur.

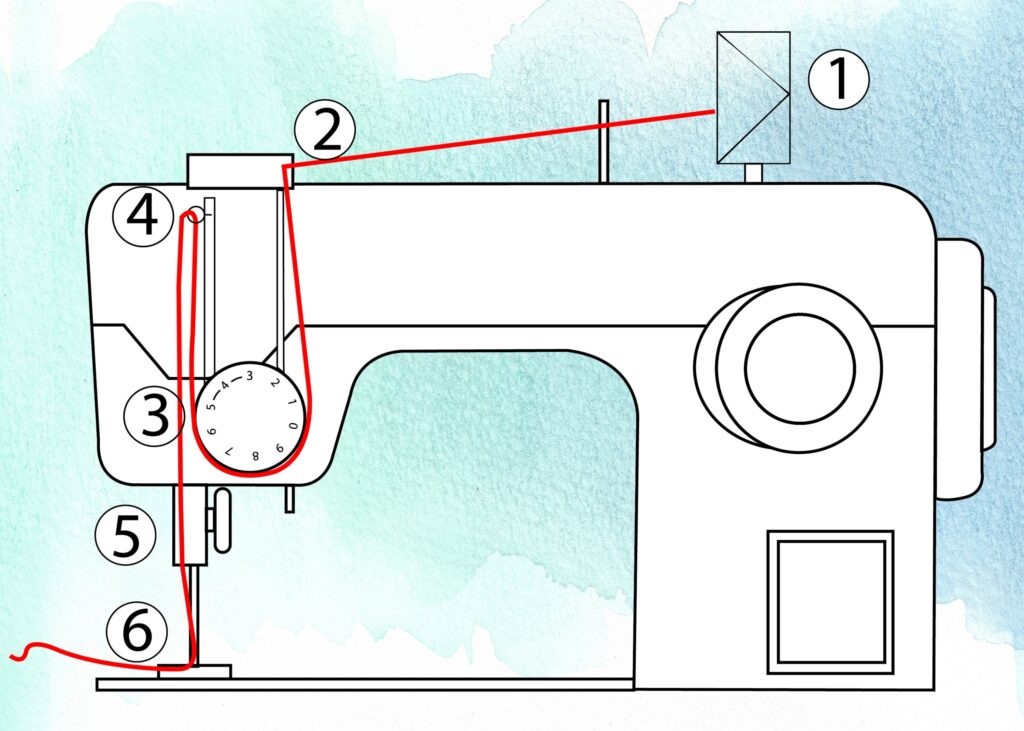

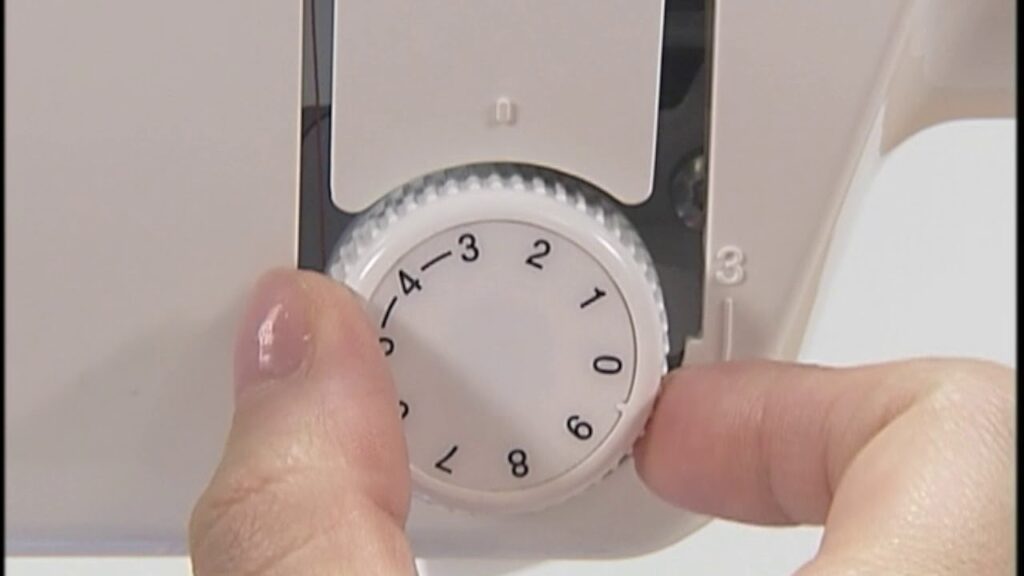

Your sewing machine actually has two tension adjustments. Most people are familiar with the top thread tension adjustment. On most sewing machines, a knob on the arm of the machine adjusts the tension. The adjustment either loosens or tightens the tension plates that grip the top thread.

You bobbin case also has a tension adjustment. In most cases, this is a very small screw on the bobbin case. We don’t recommend that most sewing machine users adjust the bobbin tension.

Troubleshooting Problems with Tension Adjustments

There is a lot more to troubleshooting tension problems than ensuring that the give and take are equal. Many other things can affect the formation of your stitches. These appear as tension issues but other problems are the real cause. Before you go blindly adjusting the tension on your sewing machine, make sure you don’t have one of these problems.

Proper Threading

Probably the most common error that can cause problems with your stitches is improper threading. Sewing machines are particular about threading. You should follow the guidelines in your user’s manual to ensure that the thread path is correct.

Many times, thread will become looped or snagged on some other part of your machine such as the screws on the needle bar or on the foot bar. A loop around the thread lifter can also cause major problems.

Dirty Tension Plates

Lint, fabric debris, or sizing build up on the inside of the tension plates can cause major problems. This is often hard to diagnosis. We don’t advocate that you disassemble the tension adjuster. Only a trained technician should diassemble the tension adjuster. You can take a strip of cloth and use it to floss your tension plates. This may be difficult on machines with tension assemblies hidden inside the arm covers.

A symptom of dirty tension plates can include:

- Jumping or skipping stitches

- Uneven stitch length

- broken thread

- ill formed stitches that occur irregularly while sewing.

Old or Inexpensive Thread

Thread is often a contributing factor to tension issues. Our recommendation is to only use new, high-quality thread on your sewing machine. Old thread is often brittle or stiff and doesn’t flow well through the machine and the tension assembly. Cheap thread often leaves lint and thread dandruff all over your machine. We have found that using new, high-quality thread often solves issues with thread tension problems.

Damage to the Machine

It doesn’t take much to interfere with thread tension or stitch formation. A small burr on the hook, the bobbin case, or the bobbin itself can cause havoc with tension and thread feeding. This kind of damage is often caused by a needle strike. All too often the damage is so slight that it is almost impossible to find.

If you suspect that any of these parts of your sewing machine have been damaged, even if you can’t see anything, have a certified technician look at the machine. The technician knows what to look for and how to find even the smallest amount of damage that can interfere with your sewing machine operation.

Tension Adjustments shouldn’t cause Tension

It is common to need to adjust the tension on your machine regularly. Different fabrics, different needle sizes, different stitch setting, and even different thread can require an adjustment to tension. It’s all a matter of give and take. Don’t be afraid to make minor adjustments to the tension on your machine to find that setting that creates those perfect stitches.

We do have some tips and tricks to help you take the stress out of tension adjustments.

- Make small adjustments.

- Test sew after each adjustment and look at both the top and bottom of the stitches.

- Make sure that the machine is threaded correctly.

- Clean the tension adjuster plates if possible.

What if you Still Have Problems?

If you just can’t get the tension set correctly it may be time to have a certified professional technician, have a look. There may be a more serious issue, or your machine may need to be serviced and cleaned.

Call The Stitch Doctor Today

If it has been a while since your sewing machine had a full-service appointment, call the Stitch Doctor today to schedule a visit.

Call 1-806-252-4471

Use our contact form to leave a message for us at this link.